INDUSTRIAL POWER RESISTORS

Industrial Power Resistors

Our resistance units are regulary supplied for in the following industries and applications:

INDUSTRIES

- Generation

- Oil, Gas and Petrochemical

- Distribution Subtation

- Gas Compressor Station

- Rollings Mills

- Electric Traction

- Testing Station

APPLICATIONS

- Industrial Heaters

- Neutral Grounding Resistor (NGR)

- Dynamic Braking Resistors (DBR,S)

DBR,S are used to absorb the energy generated when stopping electric motors. They must be able to absorb this energy and cool down quickely between stops.

- Motor starting and speed control Resistors

Resistors are used where simplicity, relability and robust constraction are Key consideration for example: in mining locomotive

- Testing

BORNA makes Resistor for testing:

- Batteries

- Power supplies

- Stand by power systems

- Dummy Load

- Load Banks

- Capacitor charge / discharge Resistors

- Cranes and other load equipments

- Bow Thrustors

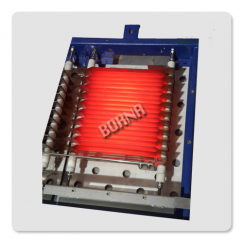

Band Heater

BORNA Band heaters can be found is available in several types different dimensions, wattage, voltages and material. Mica band heaters are an inexpensive (type of) heating that surround pipes and tubes requiring external indirect heating. Pipe heating, drum heating and barrel heating are normally used for oils, lubricants, or any other circular applications. Band heaters use electric heating elements, usually Ni- Cr wire to heat-up the external surface of drums or pipes for a gradual heat transfer. Band heating is an indirect form of heating and offer safety when heating volatile explosive substances as well as pipes or containers that cannot otherwise be heated using direct heating methods. Industrial band heaters can be made with NEMA 1 terminal boxes or NEMA 4 moisture resistant terminal boxes that protect terminations and have the option of a thermostat or thermocouple digital controllers to help control and regulate an applied heat. Outer Insulation is also required to help direct the heat to your application rather than heat loss, and slower heat-up time.

BORNA Band heaters are the ideal solution for high watt densities and high operating temperature applications, especially for the Petrochemical industry. The various types of band heaters available at Borna co include mica insulated band heaters and ceramic band heaters.

Specification

- Nickel-chrome wire in outer wall composed of interlocking ceramic tiles

- Inside medium-high: temperature heaters up to 650°C

- Outside shell temperature: 110° – 80°C

- Built-in ceramic fiber insulating mat

- Stainless steel jacket

- Minimum diameter: 56mm

- Minimum width: 25mm

- Thickness with 6mm insulation: 16mm

- Regular gap: 10mm

- Maximum watt density: 7 w/cm2

- Broad range of terminal types and thicknesses of ceramic fiber insulation mats are available.

Application

- Injection molding

- Blow-molding

- Plastic extrusion

- Container, pipe, or tank heating

- Pharmaceutical applications

- Applications in the food industry

- Drum heating

Features & Benefits

- Energy efficient

- Energy saver

- Highly flexible

- Durable

- Maintains heat

- Provide uniform heat distribution

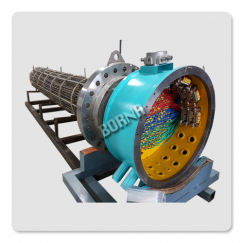

Flanged Heaters

Flanged industrial immersion heaters are commonly used in several chemical, petroleum and water based applications. Consisting normally of an ANSI rated flange with several hairpin elements or bugle tubular elements extending from the face of the flange, this electric heater uses direct heat application to the liquid medium. A thermo well is often used within the bundle of elements to allow for a probe (either a thermocouple, RTD or basic mechanical thermostat) to relay temperature readings to a digital controller that cycles and maintains the desired target temperature. Often a high limit sensor is also used to help protect liquid mediums from overheating and offers the flanged heater protection as well.

BORNA flanged immersion heaters allow the flexibility of using many different alloys to prevent corrosion and maintain life longevity of the flanged heater. Steel flanges are typically used for lubricant oils, heavy and light oils, waxes as well as mildly corrosive liquids and low flow gas heating. Process water, soap and detergent solutions as well as demine realized or deionizer water applications often use steel flanges.

Stainless steel flanged heating elements are used with mildly corrosive solutions as well as severe corrosive solutions. Food applications also use stainless steel for sanitary purposes. The sheath materials used can be steel, stainless steel, copper as well as exotic alloys such as inconel and titanium. Extremely corrosive environments such as exposure to salt water should use exotic alloys such as titanium to avoid sheath breach over excessive durations. Industries that use exotic alloys can include military, chemical and process industries.

Specification

- Watt densities up to 15.5 W/cm2

- Power rating up to 3 MW

- Passivity 316 stainless steel sheath for working temperatures up to 650°C

- 304 stainless steel sheath for working temperatures up to 650°C

- Steel sheath for working temperatures up to 400°C

- Copper sheath for working temperatures up to 175°C

Application

- Deionized water

- Demineralized water

- Clean water

- Potable water

- Process water

- Industrial water rinse tanks

- Vapor degreasers

- Hydraulic oil, crude, asphalt

- Lubricating oils at API specified watt densities

- Air and gas flow

- Caustic solutions

- Process air equipment

Features & Benefits

|

Features |

Benefits |

|

ANSI and ANSI compatible 3 ,21/2 ,2 thru 48 inch flanges |

Provides appropriate heater size-to-application and fit |

|

Element sheath and flange materials |

Meets your application needs |

|

Integral thermo wells |

Provides convenient temperature sensor insertion and replacement without draining the fluid being heated |

|

Standard, general purpose (NEMA 1) terminal enclosure |

Offers easy access to wiring |

|

All units are inspected and/or tested |

Ensures element-to-flange pressure seals do not leak |

|

Drilled and tapped eyebolt holes or lift lugs for eye bolts on 10 inch and larger flange heaters |

Facilitates lifting during installation |

|

Element support |

Provides proper element spacing to maximizing heater performance and life |