Corrosion Monitoring

To increase safety, reduce environmental impacts, reduce operating costs including reduce maintenance / inspection costs and minimize off-schedule sudden shutdowns, optimize the efficacy of inhibitor injection speed processes, oxygen concentration and fluid velocity, and investigate the impact of operational / unexpected changes, corrosion and corrosion rate control programs applied to the system must be continuously monitored and evaluated.

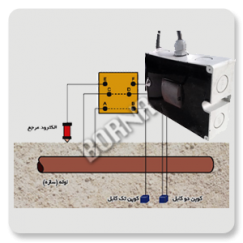

Corrosion monitoring methods include the use of corrosion coupons, electrical resistance (ER) probes, linear polarization resistance (LPR) probes, hydrogen probes, bacterial and chemical analyzes, and so on.

Borna Electronics delivers the monitoring equipment required by various industries using state-of-the-art technology following precise control steps.