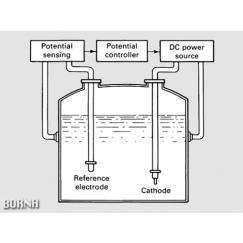

Acid Carry, Process and Storage Tanks Anodic Protection

Most of the anodic protection application is in transport tanks (trucks, trains, boats, etc.), process and storage of acids and especially sulfuric acid, which is produced more than any other chemicals worldwide. Anodic protection has been successful in maintaining product quality by reducing metal removal by corrosive solution, extending the service life of tanks and allowing the use of lower cost alloys. Practical studies have shown that the corrosion rate of tanks in the anodically protected state is approximately 10-fold lower than that of the unprotected.

Hydrogen gas is always produced as a sub product of acid corrosion. This gas can damage steel tanks. This damage is caused by the flow of gas to the valves and the dissolution of solid corrosion products on the surface of the tank, resulting in a groove in the tank. The width and depth of the grooves created can vary, and metal loss in these areas occurs much more rapidly than uniform corrosion at similar acid concentrations and temperatures. Anodic protection reduces corrosion reactions as well as the sub product of hydrogen decrease and thus prevents hydrogen groove damage.

Borna Electronics Co. declares its readiness to design, procurement, consultation and construction of anodic protection systems for acid carry, process and storage tanks in related industries.