Ships and Vessels Cathodic Protection

Ships and vessels are subject to more severe corrosion than fixed offshore structures due to their mobility at sea and at their speed. Cathodic protection for ships and vessels is used as a complementary coating method. The ships and vessels cathodic protection consists of the ship hull and their tanks and is performed in both sacrificial anode and impressed current methods.

Due to its ease of installation, operation under different conditions and easier maintenance, the sacrificial anode method is more common, although the use of impressed current methods on ships and vessels is also increasing day by day. Each of these methods is selected based on the available facilities, constraints, and designer experience.

Selection criteria of cathodic protection method in ships and vessels

| Cathodic protection method | Sacrificial anode | Impressed current |

| Need electricity | No | yes |

| Lifetime protection | Up to 5 years | At least 20 years (Expandable up to 30 years) |

| Probability of current interactions and destructive effects on adjacent structures |

No |

In some cases during the mooring |

| Ability to install smart equipment | No | Yes |

|

The most common anodes used |

Aluminum |

(Mixed metal oxide (MMO |

| Zinc | Lead- Silver | |

| Magnesium | Platinized | |

|

Most useful anode |

Zinc due to more uniform corrosion and surface erosion resistance to water flow | Mixed metal oxide (MMO) due to its greater environmental compatibility and cost-effectiveness |

A view of a vessel repairing and installing anode

In rare cases where small vessels operate in rivers or freshwater, magnesium anodes may be used to protect them cathodically. Also for the cathodic protection of the drinking water tank of the vessels, only magnesium anode and usually high potential type are used and the use of aluminum and zinc anodes is not permitted due to their harmful health elements.

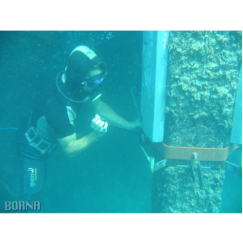

Installing aluminum anodes for cathodic protection of vessels by sacrificial method

In the ships and vessels cathodic protection by sacrificial anode method, the anodes are mounted at equal intervals on the hull and at various points on the vessel tanks to protect them. The number, shape, and position of the anodes installed in the structure to provide the required protection through relevant calculations and designer experience are obtained so that a point is not adequately protected or possibly interferes with the performance of the anodes. In the ships and vessels cathodic protection by sacrificial anode method, the design life is usually based on the timing of the dry dicking so that the anodes can be replaced in a timely manner during the repair process.

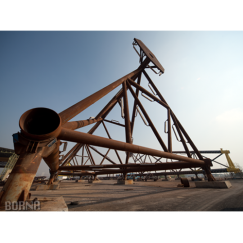

Installing lead-silver anodes in cathode protection of vessels by impressed current method

Borna Electronics Co. with over 30 years of experience in cathodic protection, declares its readiness to design, procurement, consultation and construction of cathodic protection systems for ships and vessels and implement cathodic protection monitoring systems for them.