Reinforced Concrete Jetties and Coastal Structures Cathodic Protection

Reinforced concrete jetties are subject to damages and loss of strength due to exposure to corrosive marine environment and over time. Therefore, the stability and strength of these structures should always be considered.

Although the alkaline property of the concrete has an inherent protection for the reinforcement, the presence or penetration of even small amounts of chlorine, which is abundant in the environment, interferes with this inherent protection and unforeseen corrosion attack. Widespread corrosion of concrete bars results in weakening of the concrete stability and strength and consequently of concrete destruction. The method that is widely used as a preventive in new jetties and in existing jetties to protect corrosion of bars is cathodic protection. The reinforced concrete jetties cathodic protection can include both the deck and its concrete piles and is usually performed in both sacrificial anode and impressed current methods. Each of these methods is selected based on the available facilities, constraints, and designer experience.

Selection criteria of cathodic protection method in reinforced concrete jetties

|

Cathodic protection method |

Sacrificial anode |

Impressed current |

|

Need electricity |

No |

yes |

|

Lifetime protection |

Up to 10 years |

At least 20 years |

|

Probability of current interactions and destructive effects on adjacent structures |

No |

Depending on the anode bed |

|

The most common anodes used

|

Aluminum |

High silicon cast iron |

|

Zinc |

Mixed metal oxide (MMO) |

|

|

Magnesium |

Platinized |

|

|

Most useful anode |

Zinc due to its more uniform corrosion and cost-effectiveness |

Mixed metal oxide (MMO) due to its ease of installation and cost-effectiveness |

Mixed metal oxide (MMO) anode is also the most common impressed current anode that is used depending on the conditions in the form of tubular, ribbon, mesh ribbon, mesh and etc. The cathodic protection anodes can be mounted both on the exterior surface of the structure after construction and during construction and concreting. Another type of anode location is bed away from the structure. Regarding new structures due to the type of access and ease of installation, it is usually recommended that the anodes be installed even when the structure is running.

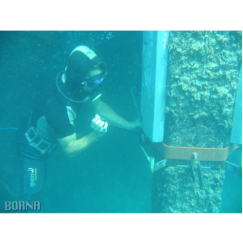

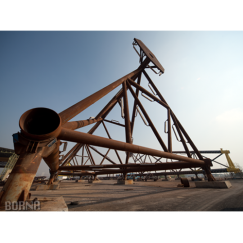

Installing zinc anodes in cathodic protection of reinforced concrete jetty piles by sacrificial anodes

Installing ribbon MMO anodes in cathodic protection of reinforced concrete jetty piles by impressed current

Borna Electronics Co. with over 30 years of experience in cathodic protection, declares its readiness to design, procurement, consultation and construction of cathodic protection systems for existing reinforced concrete jetties (to protect corrosion and restoration of structures) or under construction (to prevent corrosion of structures) and implement cathodic protection monitoring systems for them.