Anodic Protection

Anodic protection is a type of corrosion protection of metals by stabilizing the passive oxide layer on their surface. In this method, in contrast to the cathodic protection method that is applied current into structure, the current is stretched from structure until the passive metal layer is stabilized, then current stretching continues at a very low rate to maintain the stability of the passive layer and to reduce its corrosion to a minimum.

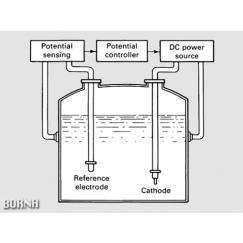

Anodic Protection Systems Performance

Potentiostat is one of the main components of the anodic protection system, which has the task of potential feedback from the reference electrode, maintaining the potential within the specified range through current changes and applying current.

Anodic Protection Potentiostats

The cathode is one of the main components of the anodic protection system, which is responsible for completing the circuit. The anodic protection cathode shall be have good corrosion resistance and may have different chemical composition depending on the corrosive environment.

Anodic Protection Cathodes

Reference electrodes are one of the main components of anodic protection system which shall be corrosion resistant in addition to their potential stability in corrosive environment. The electrode can have different chemical composition depending on the type of corrosive medium.

Anodic Protection Reference Electrodes

Most of the anodic protection application is in transport tanks (trucks, trains, boats, etc.), process and storage of acids and especially sulfuric acid, which is produced more than any other chemicals worldwide. Anodic protection has been successful in maintaining product quality by reducing metal removal by corrosive solution, extending the service life of tanks and allowing the use of lower cost alloys. Practical studies have shown that the corrosion rate of tanks in the anodically protected state is approximately 10-fold lower than that of the unprotected.

Acid Carry, Process and Storage Tanks Anodic Protection

Acid heat exchangers anodic protection are another anodic protection application. Anodic protection can include shell and tube, spiral and plate type converters.

Acid Heat Exchangers Anodic Protection

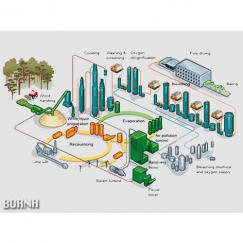

One of the applications of anodic protection is the protection of batch digesters in the kraft process of paper mills. The kraft process is a process for converting wood into paper pulp, which often involves pure cellulose fibers and the original composition of the paper. There are now several commercial applications of anodic protection to protect batch and continuous digesters and kraft liquid storage tanks.