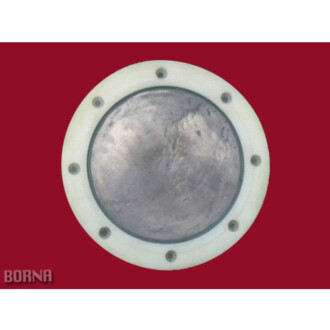

Platinized Anodes

Platinized anodes are made of two parts: base metal and coating. Titanium is used as the base metal and a very thin layer of platinum is applied to it. Titanium acts as the anode body and conductor and platinum coating as the anode active element. Base metal can be used in many different forms, including rods, tubes, meshes, etc. Conventional platinum coating thickness is about 2.5 microns, but if used in more corrosive environments, this thickness should be increased to about 5 microns.

Platinum coating thickness and anode output current density determine the useful life of the anode. The maximum voltage between anode and the environment in environments containing chlorine ions shall not exceed 8 volts because at higher voltages there is a possibility of local corrosion of the bare parts. Platinized anodes should not be used in environments containing fluoride ions because titanium oxide dissolves in such environments and anodic passivation cannot protect the base metal.

Output current density and consumption rate of platinized anodes

|

Property |

Requirement |

|

Maximum output current density |

3000 A/m2 |

|

Common output current density |

100-1000 A/m2 |

|

Consumption Rate (in 550 A/m2 current density) |

0.01 g/A.Year |

The main advantage of platinized anodes is that they can operate at high current densities with very low consumption rates. These anodes are also lighter and smaller than the conventional ones.

Borna Electronics Co. declares its readiness to design and manufacture all types of platinized anodes based on the requests of respected clients or project needs.