Impressed Current Anodes

High silicon cast iron anodes are the most common anodes used in impressed current systems and in soil buried facilities. The presence of silicon and high chromium in the high silicon cast iron anodes increases the corrosion resistance and can guarantee the long life of the protected installations. For better output current of high silicon cast iron anodes, coke breeze is commonly used in anode beds or the anodes are placed in bed with canisters containing carbonaceous backfill. The recommended place to use this type of anode compared to newer anodes such as MMO is dry environments that perform better in the long life.

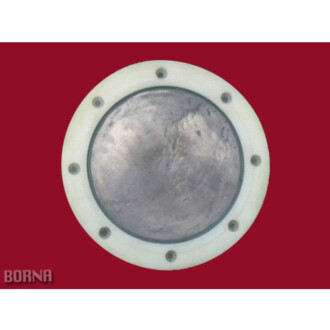

High Silicon Cast Iron Anodes

MMO anodes are consist of two pants: base metal and coating. Using Titanium as the base metal is because of having necessary characteristics for receiving coating to resistance against aggressive chemical environments and it’s appropriate conductivity. Other benefits of titanium include its lightness and use in various forms, including tube, ribbon, wire, mesh and sheets.

Mixed Metal Oxide (MMO) Anodes

Platinized anodes are made of two parts: base metal and coating. Titanium is used as the base metal and a very thin layer of platinum is applied to it. Titanium acts as the anode body and conductor and platinum coating as the anode active element. Base metal can be used in many different forms, including rods, tubes, meshes, etc. Conventional platinum coating thickness is about 2.5 microns, but if used in more corrosive environments, this thickness should be increased to about 5 microns.

Platinized Anodes

Lead-silver anodes are designed for use in the marine industry, especially for vessel protection. Formation and preservation of the lead oxide layer on the anode surface, which is an insoluble oxide, is essential and therefore alloys lead with other metals that stabilize this layer. In this type of anode, the formed layer flows current and lead acts only as a conductor and source of lead oxide.