Mixed Metal Oxide (MMO) Anodes

MMO anodes are consist of two pants: base metal and coating. Using Titanium as the base metal is because of having necessary characteristics for receiving coating to resistance against aggressive chemical environments and it’s appropriate conductivity. Other benefits of titanium include its lightness and use in various forms, including tube, ribbon, wire, mesh and sheets.

MMO Anodes coating are very thin (a few microns) and they can be operated on the base metal in different ways. Depend on the form of usage these coatings can be mixed of two or more metal oxides such as Iridium oxides, Tantalum oxides, Ruthenium oxides and Titanium oxides.

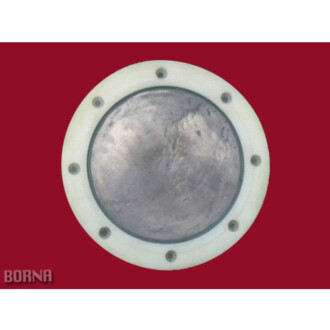

Cross-sectional image of MMO anodes manufactured by Borna Electronics Co.

Microscopic structure image of MMO Anodes coat manufactured by Borna Electronics Co.

By using this coating as an activation agent, over potential for releasing anodic chlorine and oxygen decrease considerably. Since catalyzed coating of MMO Anodes creates a low resistance for anodes, it results in less consumption rate considering it’s lifetime. Depend on environmental conditions and the kind of application MMO Anodes has extremely low consumption rate about less than 1 mg/A.Year.

These anodes are used in impressed current cathodic protection systems to resist corrosion of metal base structures. Most of these anodes are used in the maintenance of bridges, marine structures, offshore platforms, storage tanks bottom, buried or submerged pipelines, and reinforced concrete structures.

MMO anodes generally have the following benefits:

- Flexibility

- Possibility of producing anode in different Shapes

- Easy portability

- Low weight

- High output current

- Long lifetime even at very high current Density

- Dimensional stability

- Possibility of recoating

- Reliability

Output current density and lifetime of MMO anodes

|

Environmental conditions |

Maximum output current density (A/m2) |

Life time (Year) |

|

Carbonaceous backfill |

50 |

25 |

|

Petroleum Coke |

100 |

25 |

|

Fresh water |

100 |

25 |

|

Saline water |

100-300 |

25 |

|

Sea water |

600 |

25 |

Common shapes of cathodic protection MMO anodes with their applications and technical specifications are as follows:

Tubular MMO anodes

Tubular MMO anodes are used to cathodic protection of metal structures buried in soil or submerged in water. The titanium substrate of these anodes is selected according to ASTM B338 Grade 1 or 2 standard requirements. For better output current of MMO anodes, coke breeze is commonly used in anode beds or the anodes are placed in bed with canisters containing carbonaceous backfill.

Part of the producing line process of MMO Anodes of Borna Electronics Co.

Maximum output current and lifetime of tubular MMO anodes according to different dimensions and environmental conditions

|

Environmental conditions |

Anode Dimensions |

Output Current (A) |

Life time (Year) |

|

Soil, Cock and Fresh water

|

(3.4 in×48 in) 19 mm×1220 mm |

7 |

25 |

|

(1 in×19.7 in) 25 mm×500 mm |

4 |

25 |

|

|

(1 in×39.4 in) 25 mm×1000 mm |

8 |

25 |

|

|

(1 in×48 in) 25 mm×1220 mm |

3.5 |

25 |

|

|

(1 in×60 in) 25 mm×1500 mm |

4.5 |

25 |

|

|

(1.25 in×48 in) 31.75 mm×1220 mm |

12 |

25 |

|

|

Sea water

|

(3.4 in×48 in) 19 mm×1220 mm |

45 |

25 |

|

(1 in×19.7 in) 25 mm×500 mm |

25 |

25 |

|

|

(1 in×39.4 in) 25 mm×1000 mm |

50 |

25 |

|

|

(1.25 in×48 in) 31.75 mm×1220 mm |

75 |

25 |

Ribbon MMO anodes

Ribbon MMO anodes are used to cathodic protection of pipelines and tanks. The titanium substrate of these anodes is selected according to ASTM B265 Grade 1 standard requirements. A Conductor bar is used to connect the ribbon anodes to each other and impressed current into the anode lattice. The conductor bar is pure titanium and its chemical composition complies with ASTM B265 Grade 1. Ribbon MMO anodes and conductors are interconnected at the tanks bottom and connected to each other using spot welding.

Titanium power feed is used to connect the rectifier transformer positive cable to the anodic lattice of the tanks bottom. Power feed connection to the anodic lattice is also accomplished by spot welding.

An example of Ribbon MMO anodes manufactured by Borna Electronics Co.

Dimensions and weight of conventional ribbon MMO anodes

|

Width |

6.35 mm (0.25 in) |

|

Thickness |

0.635 mm (0.025 in) |

|

Standard coil length |

100 m |

|

Standard coil weight |

1.5 kg |

|

Surface area of ribbon |

0.014 m2Per/m |

Maximum output current and life time of conventional ribbon MMO anodes

|

Environmental conditions |

Output current (mA/m) |

Approximate life time (Year) |

|

Fine sand |

42 |

50 |

|

Concrete |

1.5 |

100 |

Mesh ribbon MMO anodes

Mesh ribbon MMO anodes are used to cathodic protection of reinforced concrete structures. The titanium substrate of these anodes is selected according to ASTM B265 Grade 1 standard requirements.

Maximum Output Current and Life time of mesh ribbon MMO anodes in concrete by according their width

|

Width (mm) |

Output current (mA/m) |

Approximate life time (Year) |

|

10 |

2.75 |

75 |

|

13 |

3.7 |

50 |

|

3.5 |

100 |

|

|

15 |

4.1 |

50 |

|

3.9 |

75 |

|

|

20 |

5.6 |

50 |

|

4.9 |

75 |

|

|

4.7 |

100 |

Wire MMO anodes

Wire MMO anodes are used to cathodic protection of buried metal structures in soil such as pipelines and tanks bottom. The titanium substrate of these anodes is selected according to ASTM B863 Grade 1 standard requirements. Wire MMO anodes may be supplied with carbonaceous backfill (Coke Breeze). Wired MMO anodes with cable, coke breeze and protective coating are called “piggy backs”.

An example of wire MMO anodes manufactured by Borna Electronics Co.

Maximum output current of wire MMO anodes according to their size

|

Wire Diameter (mm) |

Output current (A/m) |

||

|

Sea water |

Fresh water |

Soil with Backfill |

|

|

1.5 |

3 |

0.5 |

0.5 |

|

3 |

6 |

1 |

1 |

Connecting wire MMO anode to cable with HMWPE/PVDF coating

Other MMO anodes

Other MMO anodes can be disk, probe, rod, strip, mesh, mesh tube, etc., depending on their specific application conditions.

Borna Electronics Co. declares its readiness to design and manufacture all types of MMO anodes based on the requests of respected clients or project needs