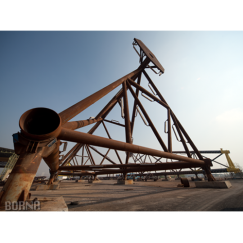

Metal Jetties and Coastal Structures Cathodic Protection

Metal jetties are subject to corrosion in the marine environment due to the presence of a significant portion of the structures in the areas of marine sediments, immersed zone, tidal zone and splash zone.

The corrosion phenomenon is more severe in parts of the surface exposed to seawater continuous spraying (splash zone) and wet and drying one to two times during the daytime (tidal zone) because sea salt deposition during drying period on the surface increases the concentration of corrosive ions and intensifies the attack. The corrosive intensity of the environment and the economic and strategic importance of the metal jetties make the use of cathodic protection inevitable.

Schematic of levels and areas in the marine environment

Cathodic protection of metal jetties is usually performed as a complementary coating method and in both sacrificial anode and impressed current methods. Each of these methods is selected based on the available facilities, constraints, and designer experience.

Selection criteria of cathodic protection method in metal jetties

| Cathodic protection method | Sacrificial anode | Impressed current |

| Need electricity | No | yes |

|

Lifetime protection |

Up to 10 years |

At least 20 years (Expandable up to 30 years) |

| Probability of current interactions and destructive effects on adjacent structures | No | Yes |

|

The most common anodes used

|

Aluminum | High silicon cast iron |

| Zinc |

Mixed metal oxide (MMO) |

|

|

Most useful anode |

Aluminum due to higher current capacity | Mixed metal oxide (MMO) due to cost-effectiveness |

In the metal jetties cathodic protection, anodes are mounted in immersed parts of the jetty (such as piles) to protect the structure. The anodes used in the sacrificial anode method are flush mounted and are attached to the structure by welding or screwing through the core. The anodes used in the impressed current method are vulnerable to physical and mechanical damage to the marine environment, so it is recommended that these anodes be enclosed in a non-metallic sheath to prevent damage caused by waves and other external factors.

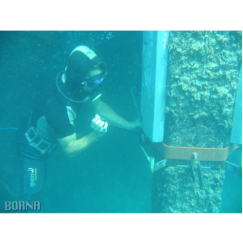

Installing aluminum anodes in cathodic protection of metal jetty piles by sacrificial method

Borna Electronics Co. with over 30 years of experience in cathodic protection, declares its readiness to design, procurement, consultation and construction of cathodic protection systems for metal jetties and coastal structures and implement cathodic protection monitoring systems for them.