High Silicon Cast Iron Anodes

High silicon cast iron anodes are the most common anodes used in impressed current systems and in soil buried facilities. The presence of silicon and high chromium in the high silicon cast iron anodes increases the corrosion resistance and can guarantee the long life of the protected installations. For better output current of high silicon cast iron anodes, coke breeze is commonly used in anode beds or the anodes are placed in bed with canisters containing carbonaceous backfill. The recommended place to use this type of anode compared to newer anodes such as MMO is dry environments that perform better in the long life.

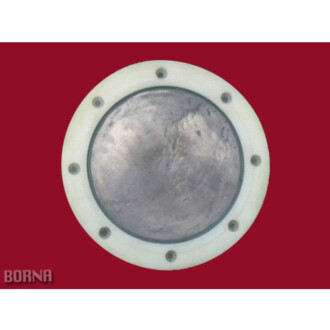

High silicon cast iron anodes with canisters manufactured by Berna Electronics Co.

The commercial name of this alloy is Tantiron and manufactured in accordance with ASTM A518 and IPS-M-TP-750 standards. The disadvantages of high silicon cast iron anodes are their high weight and their high susceptibility to impact.

Chemical composition of high silicon cast iron anodes according to ASTM A518 standard

|

Element (Wt%) |

Chemical composition |

||

|

Grade 1 |

Grade 2 |

Grade 3 |

|

|

Carbon |

0.65-1.10 |

0.75-1.15 |

0.70-1.10 |

|

Manganese |

1.50 Max. |

1.50 Max. |

1.50 Max. |

|

Silicon |

14.20-14.75 |

14.20-14.75 |

14.20-14.75 |

|

Chromium |

0.50 Max. |

3.25-5.00 |

3.25-5.00 |

|

Molybdenum |

0.50 Max. |

0.40-0.60 |

0.20 Max. |

|

Copper |

0.50 Max. |

0.50 Max. |

0.50 Max. |

Physical properties of high silicon cast iron anodes according to IPS-M-TP-750 standard

|

property |

Requirement |

|

Density |

7-7.05 g/cm3 |

|

Hardness |

500 HB Min. |

|

Compressive strength |

650 MPa Min. |

|

Electrical resistivity |

72 microohm.cm Max. |

|

Impact resistance |

0.1 J Min. |

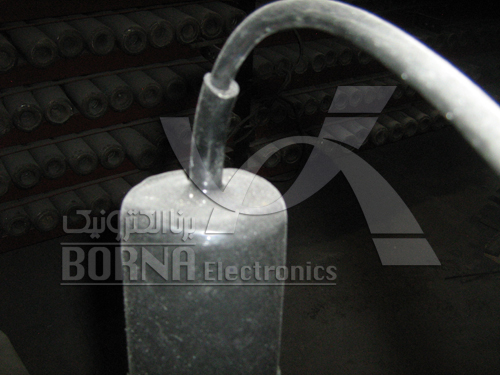

Copper cable connection to the anode is Lead Caulking type with strong and reliable connection with minimum voltage drop at the junction. The cable connection to the anode is covered with epoxy resin and a shrinkable cap is placed on it to prevent moisture from entering.

Shrinkable cap used in high silicon cast iron anodes manufactured by Borna Electronics Co.

Typically, high silicon cast iron anodes are manufactured in two sizes (diameter×length) 2×60 and 3×60 inches. The output current of 2×60 high silicon cast iron anodes in the carbonaceous backfill is about 2 amp and the output current of 3×60 high silicon cast iron anodes is about 3 amp for a design life of 25 years.

Maximum output current density and consumption rate of high silicon cast iron anodes in different environmental

|

Environmental conditions

|

Maximum output current density (A/m2) |

Consumption rate (kg/A.Year) |

|

Carbonaceous backfill |

15 |

0.10 |

|

Fresh water |

10 |

0.12 |

|

Sea water |

15 |

0.30 |

Dimensions and weight of high silicon cast iron anodes according to IPS-M-TP-750 standard

|

Anode diameter (mm) |

Anode head diameter (mm) |

Length (mm) |

Weight (kg) |

|

51 |

76 |

915 |

14.5 |

|

51 |

76 |

1220 |

19 |

|

51 |

76 |

1525 |

22.5 |

|

76 |

102 |

915 |

29 |

|

76 |

102 |

1220 |

38 |

|

76 |

102 |

1525 |

49 |

Borna Electronics Co. declares its readiness to design and manufacture all types of high silicon cast iron anodes based on the requests of respected clients or project needs.