Corrosion Monitoring

Corrosion monitoring involves the use of methods and equipment to measure corrosion rates either offline or online in real time, with the aim of more effective system maintenance and implementing or improving preventive measures to combat and protect against corrosion. Corrosion monitoring also helps reduce operational costs, minimize sudden failures and unexpected incidents, increase safety, decrease environmental impacts, and optimize the efficiency and rate of corrosion inhibitor chemical injection. Corrosion monitoring is a process for detecting, measuring, and tracking the corrosion rate in materials, especially metals, which is used in industries such as pipelines, storage tanks, refineries, power plants, and more. The purpose of corrosion monitoring is to prevent failure, maintain structural integrity, optimize maintenance, and ensure safety.

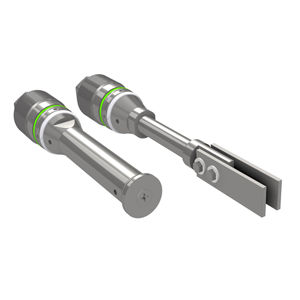

In this regard, a large portion of corrosion monitoring tools includes corrosion coupons (CC) and corrosion probes (CP).

Borna Electronics Co. with over 40 years of experience in the industry, declares its readiness to design, procurement of equipment, consultation and construction of corrosion monitoring systems.