Plugs

Plugs are key components of access fitting assemblies and act as seals within the access fittings to maintain line pressure at the point where the fitting is installed. On the other hand, this device connects to the coupon holder or probe and enables the insertion and removal of the coupon or probe via a Retriever. When the plug is connected to the access fitting, it facilitates access to an operating system that is functioning at maximum operating pressure (up to 6000 psi).

Types of plugs, based on body shape and method of connection to the coupon holder or probe, include:

- Solid Plug

- Hollow Plug

Plugs produced by Borna Electronics Co are typically made of 316 or 316L stainless steel, manufactured in accordance with international standards such as ASTM A276 and ANSI/NACE MR0175/ISO 15156 (Relevant to sour environments), and they can also be customized based on customer requirements. In environments with extremely severe corrosive conditions, materials with higher corrosion resistance, such as Duplex stainless steel, Nitronic, Inconel 625 or …, can be used.

The components of a solid plug include: Solid Plug body, Primary Packing, Pipe Plug, O-ring – Retaining Nut and Set Screw. Also, the components of a hollow plug include: Hollow Plug Body, Primary Packing, Probe Packing, Retaining Nut, Seal Nut and Set Screw.

The packing retaining nut holds the primary packing in place and ensures proper sealing when the corrosion monitoring device is not connected to the solid plug. The O-ring provides secondary sealing and protects the threads of the hole from unnecessary contact with the system fluid.

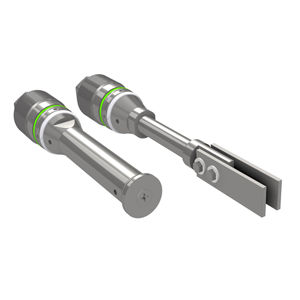

Components of the solid plug (right side) and hollow plug (left side)