Pipelines Cathodic Protection

Soil buried pipelines used to transport oil, gas, water, condensates, etc. are one of the most used equipment in industries and their external surface corrosion in addition to safety problems and in some cases environmental, Imposes damages on the industry annually.

Pipelines cathodic protection is used as a complementary coating method to prevent this type of corrosion. The pipelines cathodic protection is accomplished in two ways: sacrificial anode and impressed current and can be temporary (short-term) or permanent (long-term). In the sacrificial anode cathodic protection method, usually is used magnesium or zinc anodes with the backfill, depending on the electrical resistivity of the soil. The impressed current cathodic protection method is used cast iron (HSCI) or mixed metal oxide (MMO) anodes depending on the required current rate and design life.

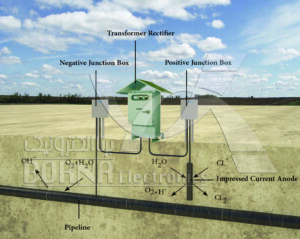

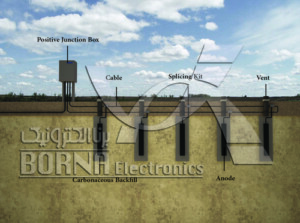

Schematic of pipelines cathode protection using impressed current method

Impressed current anodes can be positioned as horizontal, vertical, deep well or distributed (surface wells) with designated distance from it to protect pipelines. The type of anode bed is selected according to the designer’s opinion, the requirements of common cathodic protection standards and operating procedures.

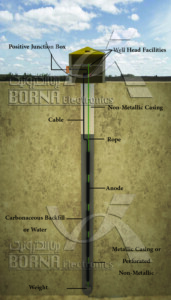

In pipelines cathodic protection with deep wells, wells are drilled at a designated distance from the pipeline and the anodes are inserted. In this type of cathodic protection anode beds, anode cables in salt or corrosive gases or ions areas shall have corrosion-resistant insulation materials such as PVDF and etc.

Schematic of deep wells

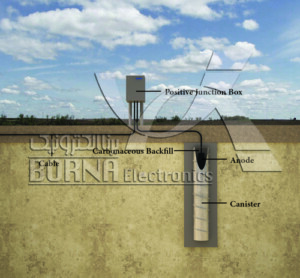

Distributed anode beds can be used in environments where standard anode bed distance from structure is not feasible and the needs to cover a limited portion of the structure by anode (due to the required current distribution for cathodic protection in distributed anode beds, the anode bed may be approached to the structure). With the creation of distributed anode beds, the content of stray currents is reduced and the efficiency of the cathodic protection system is increased. In this type of anode beds, the anodes may be installed individually or in groups. Depending on the anode installation method, the construction steps will be similar to horizontal or vertical anode beds.

Schematic of distributed anode beds using canistered anodes

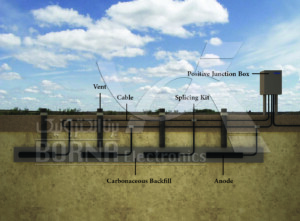

Another method for pipelines cathodic protection is the use of wire MMO anodes along the pipeline. This method provides a more uniform current distribution and higher reliability in protecting all pipe sections but is more economically costly.

Installing wire MMO anodes in pipelines cathode protection by impressed current method

Borna Electronics Co. with over 30 years of experience in cathodic protection, declares its readiness to design, procurement, consultation and construction of cathodic protection systems for pipelines and implement cathodic protection monitoring systems for them.