Laboratory Services

Borna Electronics Knowledge-Based Co, with over 40 years of distinguished experience in the electrical and corrosion industry of the country, with the aim of establishing a reputable testing center and issuing traceable certificates, utilizing the knowledge and expertise gained through years of activity in this field, has successfully obtained ISO/IEC 17025 certification from the National Accreditation Center of Iran (NACI) with accreditation number NACI/Lab/2071.

This laboratory complex, through continuous effort and investment in new and precise equipment, has established the necessary infrastructure to provide services to clients. The laboratory engineers, with scientific insight and specialized experience, offer a wide range of tests in accordance with the latest versions of international standards to esteemed employers and customers. In addition, the laboratory experts can assist clients in interpreting test results and identifying degradation mechanisms and …, which serves as a key factor in accelerating the completion of manufacturers’ and clients’ projects and plans.

Borna Electronics Laboratory, in accordance with ISO/IEC 17025 standard requirements, is capable of providing specialized services to esteemed clients from prototyping to testing and reporting. Based on this framework, 14 specialized tests in the field of corrosion have been defined and approved.

These 14 specialized tests are as follows:

- Preparation, cleaning, and corrosion evaluation of metallic samples according to ASTM G1 standard

- Cleaning and corrosion evaluation of corrosion coupons after exposure to a corrosive environment according to NACE SP0775 standard.

- Laboratory evaluation of sacrificial magnesium anodes for use in soil according to ASTM G97 standard.

- Laboratory evaluation of sacrificial zinc and aluminum anodes according to DNV-RP-B401 standard.

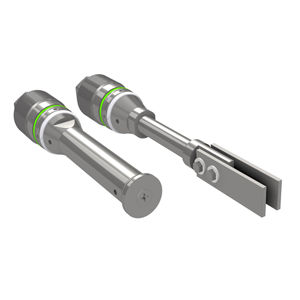

- Accelerated testing to determine the service life of MMO anodes for use in soil and natural waters according to NACE T0108 / ISO 19097-2 / INSO 15818-2 standards.

- Accelerated testing to determine the service life of MMO anodes for use in concrete according to NACE TM0294 / ISO 19097-1 / INSO 15818-1 standards.

- Acid testing of MMO anodes according to IGS-M-TP-22 standard.

- Bend and peel-off testing of MMO anodes according to IGS-M-TP-22 standard.

- Mechanical resistance testing of MMO anodes according to IGS-M-TP-22 standard.

- Measurement of electrical resistance of static electrical connections according to ASTM B539 standard.

- Particle size distribution analysis of coal and coke according to ISO 2325 standard.

- Measurement of the electrical resistivity of soil and coke using the Wenner four-pin method according to ASTM G57 standard.

- Measurement of coating thickness using magnetic field or eddy current (electromagnetic) testing according to ASTM E376

- Determination of coating adhesion degree using the tape test according to ASTM D3359 standard.

Other activities of the corrosion laboratory include conducting related tests such as chemical analysis (elemental analysis), mechanical testing, metallography, and other corrosion tests including polarization, impedance, salt spray, dezincification, cathodic disbonding, and more, as well as the analysis and identification of corrosion and failure mechanisms.

The Corrosion Laboratory of Borna Electronics Co. declares its readiness to determine the rate and type of corrosion, interpret corrosion coupon results, and analyze the causes of material failure.