Corrosion Probes

Corrosion probes are mainly electrical resistance probes and are essentially called “Automatic Coupons” with their mobile equipment which have a lot of sharing with corrosion coupons. Electrical resistance systems operate based on measuring the electrical resistance of a thin metallic element made of the same material as the structure. As corrosion occurs and metal is removed from the element, its resistance increases, and the changes in resistance compared to a reference value are converted into corrosion data and recorded by a data logger or corrosion transmitter. The most important advantage of the electrical resistance method compared to coupons is its ability to perform measurements online and more easily. In automatic and continuous corrosion monitoring systems, it is possible to detect changes in the corrosion rate and using this information, timely adjustments can be made to the type and rate of corrosion inhibitor chemical injection, as well as to process conditions.

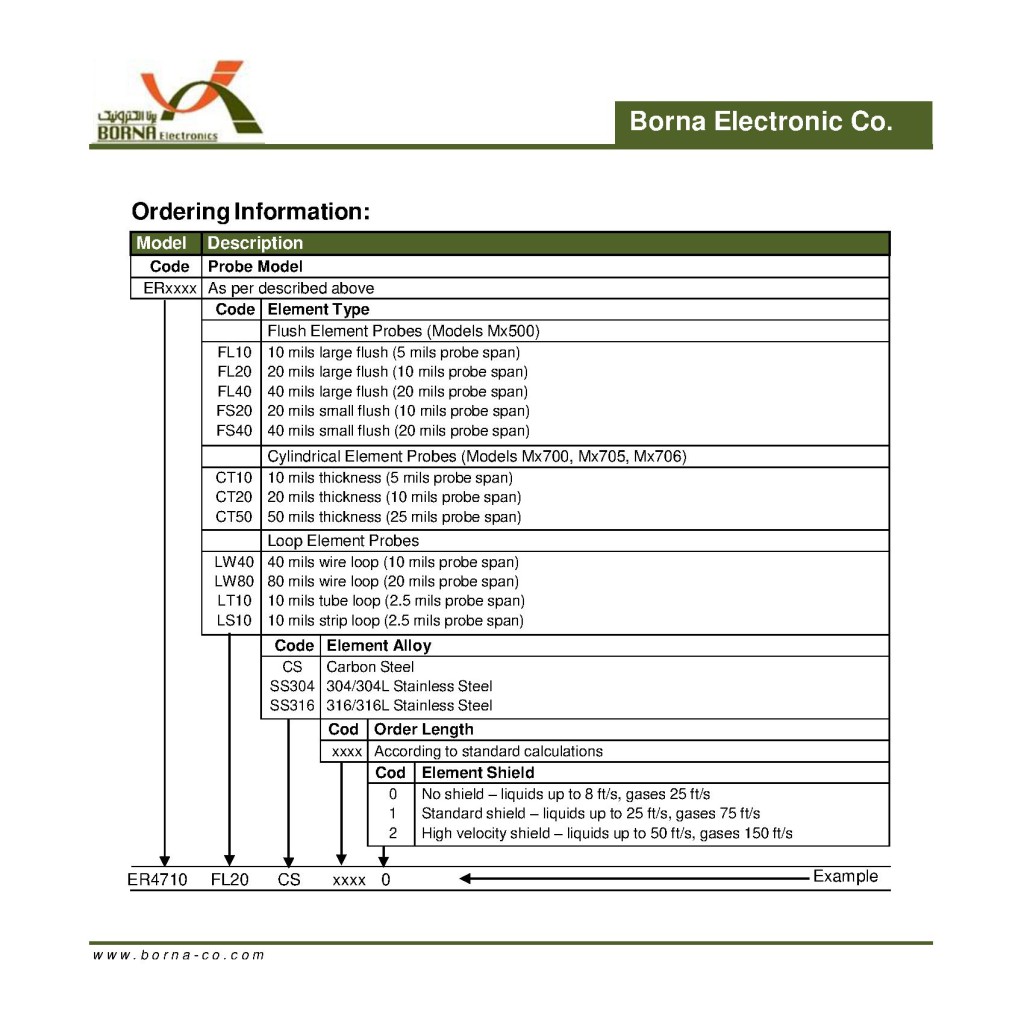

The probes produced by Borna Electronic Co. are classified into two categories based on their application: electrical resistance (ER) probes and special-purpose probes.

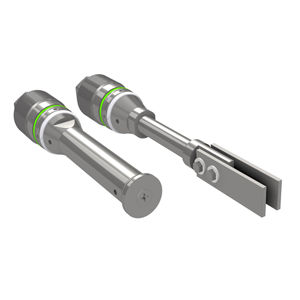

Electrical Resistance Probes (ER)

- Flush Probes

- Tubular/ Cylindrical Probes

- Tube/Ribbon/Wire Loop Probes

Special-Purpose Probes

- Linear Polarization Resistance Probes

- Hydrogen Probes

- Sand Probes

- Biological Probes

The metal elements of Borna Electronic’s probes are made from materials similar to the structure, and their bodies are usually made of 316 or 316L stainless steel. They are manufactured in accordance with the requirements of international standards, including ASTM A276 and ANSI/NACE MR0175/ISO 15156 (related to sour environments), and according to customer specifications. For environments with extremely severe corrosive conditions, alternative and suitable materials for those environments, such as duplex stainless steel, Nitronic, Inconel 625 or …, can be used.

These probes can be connected to a data logger or corrosion transmitter via a connector and a 6-pin military socket.

Corrosion probes are devices used to detect, monitor, and measure the corrosion rate in industrial systems such as pipelines, tanks, heat exchangers, and offshore platforms. Probes, by providing real-time or periodic data on metal weight loss due to corrosion, assist in predictive maintenance and the integrity management of the monitored system.

The types of probes produced by Borna Electronics Co, in terms of operating mechanism, are as follows:

- Electrical Resistance Probe (ER): The operating principle of this type of probe is based on measuring the change in the electrical resistance of a metallic element over time. This type of probe is used for long-term corrosion rate monitoring. Its advantages include accurate measurement of uniform corrosion and the ability to be used in server environments. Its drawback is a weak response to localized corrosion.

- Linear Polarization Resistance Probe (LPR): Its operating principle involves applying a small voltage to a metal electrode, measuring the resulting current, and determining the corrosion rate. It is used for continuous and real-time monitoring in conductive liquids such as water and acids. Its advantage is the rapid measurement of the corrosion rate; however, it is not suitable for non-aqueous environments and requires a conductive medium.

- Galvanic Probe: This probe uses two dissimilar metals and operates based on measuring the current generated by galvanic activity. It is used for monitoring galvanic corrosion. This type of probe is easy to use and does not require an external power source, but its accuracy for measuring general corrosion is low.

- Hydrogen Probe: Its operating principle is detecting the penetration of atomic hydrogen into steel and indicating the risk of hydrogen-induced cracking. It is used in high-pressure hydrogen environments such as refineries. Its advantage is early warning of hydrogen damage, but its application is limited and specialized.

Types of ER and LPR corrosion probes