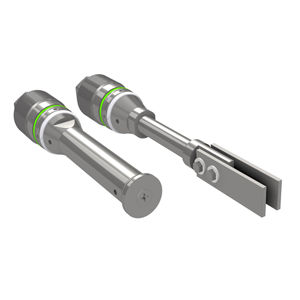

Corrosion Data Logger/Transmitters

Corrosion data loggers/ transmitters inject an electric current into the probe and, by measuring the voltage, calculate the electrical resistance of the circuit. They then record the corrosion data or transmit it to the control room.

Data Logger

A corrosion monitoring data logger is a device that collects and stores data from corrosion probes or sensors over time, allowing engineers to analyze corrosion trends and make informed maintenance decisions. It’s especially useful in remote locations or when real-time monitoring systems (e.g., transmitters) are not feasible due to cost, power, or infrastructure constraints.

It’s a compact and Hand held, often battery-powered device that:

- It continuously records data from the corrosion sensors or at specified time intervals,

- It enables long-term data storage,

- It can be easily installed and used in various locations.

- And the stored data can be transferred via USB port, memory card, or wireless connection for further analysis.

Typical Data Collected:

- Metal loss

- Corrosion rate

- Electrochemical potential

- Environmental data (temp, pH, humidity and …)

Advantages

- Offline, long-term data logging

- No need for continuous power or communications infrastructure

- Portable and resistant to moisture and dust (IP65/IP67)

- Useful in periodic inspection programs

- Ideal for remote pipelines and tanks

Limitations

- Real-time data logging not possible

- Requires manual retrieval of data (in most models)

- Limited by memory and battery life

Transmitter

A corrosion monitoring transmitter is an electronic device used to detect and transmit real-time data about corrosion activity in pipelines, tanks, or other industrial equipment. Unlike passive methods (like corrosion coupons), transmitters offer continuous, real-time monitoring, which is critical for early detection and preventive maintenance.

It’s a sensor-based device that detects corrosion (either directly or indirectly) and sends data to a control system. These devices are widely used in oil and gas, chemical processing, water treatment, and marine industries.

The key components of the transmitter include the following:

- Corrosion Probe or Sensor

- ER (Electrical Resistance) probe: Measures metal loss.

- LPR (Linear Polarization Resistance): Measures corrosion rate (mainly in conductive fluids).

- Hydrogen probes: Detect hydrogen permeation, a sign of certain types of corrosion.

- Ultrasonic sensors: Measure wall thickness non-invasively.

- Transmitter Unit:

- Collects signals from the probe.

- Converts the signal to standard outputs (e.g., 4-20 mA, Modbus, HART, or wireless).

- Power Supply:

- Power Supply (DC powered) or battery-powered for remote systems.

- Communication Interface:

- Wired or wireless (LoRaWAN, Bluetooth, cellular, etc.).

How It Works (ER Probe and Transmitter)

- A metal element in the ER probe is exposed to the environment.

- As it corrodes, its electrical resistance increases.

- The transmitter detects this change and calculates metal loss over time.

- Finally, the data is sent to the control system.

Advantages

- Real-time monitoring

- Remote access and alerts

- Early detection of rapid corrosion events

Limitations

- Vulnerability to sever environmental conditions

- Need for maintenance and repairs

- Possibility of sudden breakdown