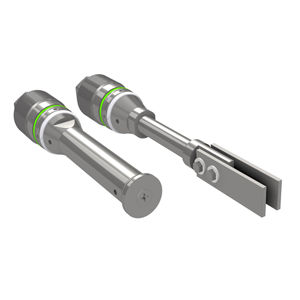

Corrosion Coupons

Corrosion coupons are mainly of the weight loss type and consist of small metal samples made of the same material as the structure. They are placed in the intended environment for a specified period of time to determine the rate, pattern, and form of metal corrosion. Although the use of corrosion coupons is a basic and simple method, it is still considered an accurate technique for corrosion monitoring. The corrosion coupons produced by Borna Electronics Co. are categorized based on their application into two main types: weight loss coupons and special-purpose coupons.

- Weight Loss Coupons

- Strip Coupons

- Disc Coupons

- Flush Disc Coupons

- Rod Coupons

- Special-Purpose Coupons

- Scale Coupons

- Biofilm Coupons

- Stressed Coupons

- Welded Coupons

- Ring Type Coupons

Weight loss coupons allow a quantitative measurement of corrosion rate in a corrosion monitoring system. Also, in some conditions morphological degradation can be attributed to a specific factor. Corrosion coupons are available in a variety of sizes and types. The size and shape of the coupons are determined by the type of used holder, line size, and the mounting position.

The size and shape of the coupons are determined based on the type of application, line size, orientation, type and number of fluid phases in the environment, etc. Depending on the system conditions, coupons can be installed using various methods. The installation must ensure adequate support for the coupons within the system, electrical isolation of the coupons (from other coupons, the holder, and the pipe or vessel wall to prevent galvanic corrosion), secure positioning of the coupon at the intended location within the system, and enable quick and easy replacement of the coupons.

Borna Electronics Co. corrosion coupons are manufactured in a variety of types, dimensions, and materials, in accordance with international standards such as NACE SP0775 and ANSI/NACE MR0175/ISO 15156 (Related to sour environments), and customer requirements. Each coupon is stamped with detailed specifications, including serial number, material, dimensions, and weight with a resolution of 0.0001 grams. These coupons are packaged in special nylon bags impregnated with vapor-phase corrosion inhibitor (VCI) and subsequently sealed in paper envelopes.

Laser engraving of serial number and material of corrosion coupons

How to weigh corrosion coupons using a balance with 0.0001 g resolution

How to package corrosion coupons in special nylons impregnated with vapor phase corrosion inhibitor (VCI)

How to pack corrosion coupons in paper envelopes