Anti-Fouling Anodes

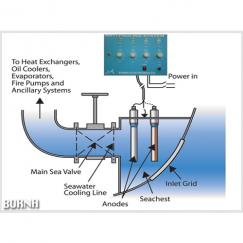

Anti-fouling copper anodes is responsible for the release of copper ions and anti-fouling aluminum anodes is responsible for the production of aluminum hydroxide. The size (diameter and length) of the anodes is determined based on seawater velocity (inlet water debit), design life, and consideration of the maintenance or dry docking schedule for the vessels. Anodes can be mounted using auxiliary equipment including steel flanges, steel sheath, etc.

For the electrical connection of the anodes, a sheathed copper cable is used and the cable is connected to the steel core inside the anode using a cable shoe. The connection is well insulated to prevent shortening.

Depending on the type of application and positioning, the sealing of these anodes is of particular sensitivity and fineness and special sealing materials should be used in their manufacturing process. The electrical continuity of the cable to the anode and the electrical insulation flange and other anode mounting equipment to anode and cable shall be evaluated after the manufacturing process, before and after the anodes are installed.

Electrical continuity test of anti-fouling anodes manufactured by Borna Electronics Co.

Borna Electronics Co. declares its readiness to design and build a variety of anti-fouling anodes based on the requests of respected clients or project needs.