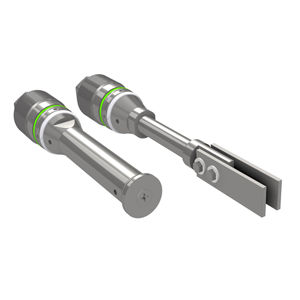

Access Fittings

High-pressure standard access fittings provide access to systems under operating conditions up to 6000 psi, eliminating the need for system shutdown to obtain corrosion data. Special access fittings are applicable for pressures up to 10,000 psi.

Once the fitting is attached to the line, it acts as the conduit through which hot tapping and … can take place. After the line is successfully “tapped in”, monitoring equipment can be exposed to the process stream by using the retriever and service valve to install either a solid or hollow plug, to which monitoring equipment can be attached. Once installed, the plug seals off the fitting, thereby maintaining line integrity.

Access fittings, based on body shape and connection method, include:

- Flareweld

- Buttweld

- Socketweld

- NPT Threaded

- Flanged

Access fittings produced by Borna Electronics Co. are typically made of A105 or A105N carbon steel, manufactured in accordance with international standards such as ASTM A105 and ANSI/NACE MR0175/ISO 15156 (Relevant to sour environments), and treated with a phosphate surface coating. They can also be customized based on customer requirements. Additionally, the company’s flanged access fittings can be provided in all temperature and pressure classes according to ASME B16.5 and API 6A standards.